Five chemical engineering research stories from September 2016

3rd October 2016

To help you stay up-to-date with the latest achievements from the chemical engineering research community here is our monthly instalment with some of the latest stories.

September's five stories of amazing chemical engineering research and innovation are:

The Popeye effect – powered by spinach

Prof. Avner Rothschild of the Faculty of Material Science and Engineering said; “The study is unique in that it combines leading experts from three different faculties, namely three disciplines: biology, chemistry and materials engineering. The combination of natural (leaves) and artificial (photovoltaic cell and electronic components), and the need to make these components communicate with each other, are complex engineering challenges that required us to join forces.”

A new paradigm for treating Parkinson's disease

While other teams have been working on generating neurons from induced pluripotent stem cells (iPSCs) and transplanting them into the brains of people with Parkinson’s, Leo Behie, Canada Research Chair in Biomedical Engineering and professor of chemical engineering says “there is potentially a significant problem with the procedure”. Even when good tissue matches are made from iPSC donor banks presently being prepared, powerful immunosuppressants may still need to be administered that weakens a person’s immune system and make them susceptible to other diseases.

Leo and his collaborators propose using computer-controlled bioreactors to generate a highly therapeutic mixture from human mesenchymal stem cells found in bone marrow, in work published in Nature. Then, the mixture — called a secretome — would be implanted into the brain. Since no cells are transplanted, there is no need to suppress the immune system.

“When the secretome is introduced into the PD brain, there is a powerful result,” says Leo. “We were able to show that the injured brains regenerated new neurons. The secretome caused the increase of dopaminergic neurons and neuronal terminals in the midbrain.” The researchers also followed the physical behaviour of the PD test animals and observed a significant physical recovery from the disease. “This is unheard of,” says Leo.

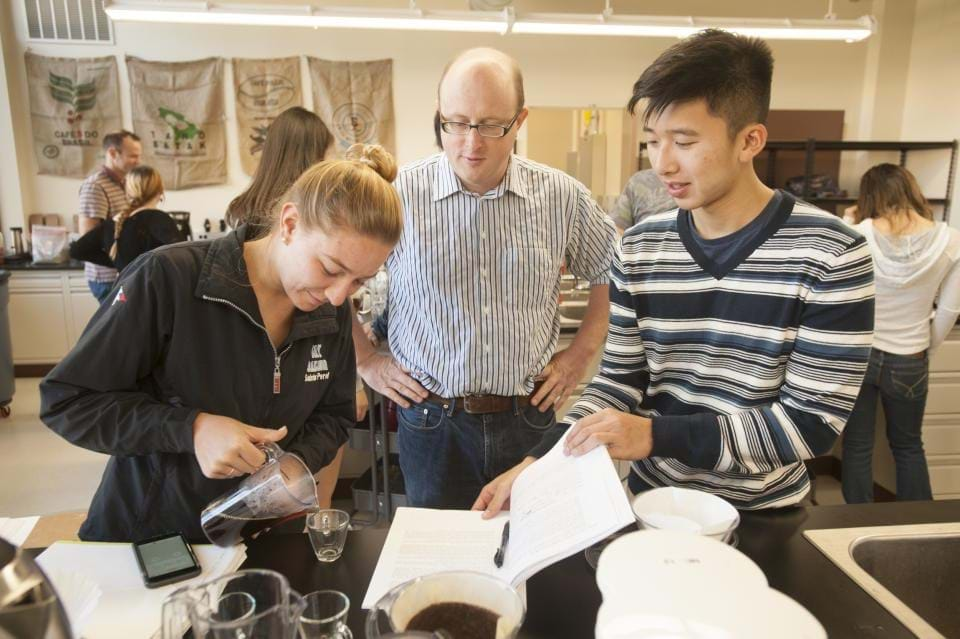

Using coffee to perk up education

The best way to give chemical engineer undergraduates a hands-on introduction to chemical engineering? Use coffee! William Ristenpart and Tonya Kuhl, two engineering professors at the University of California, Davis, had the idea of taking apart a Mr. Coffee coffeemaker to study how the designers solved the small-scale engineering challenge of brewing coffee.

Think about all those chemical reactions when you roast the beans. "The roaster we use, a chemical engineer would call that a fluidized bed reactor," Ristenpart said. When hot water extracts tiny particles of flavor and oil from the ground-up beans, "we would call that mass transfer." And what drives hot water through an automatic drip-coffee machine? Fluid dynamics, of course.

The Specialty Coffee Association of America heard about it and encouraged the two professors to create not just a class, but an entire center devoted to research on coffee. Ristenpart says there's a gaping void of academic research on coffee-making. Researchers might study what happens in the green coffee beans when they are fermented, immediately after harvest, or ways to "maximize the transfer of flavor molecules that you want" into your cup during the brewing process, while leaving those bitter-tasting molecules behind.

Using nanotechnology to make better, cheaper and healthier sanitary pads

The team's nanofibers are 200 times smaller in diameter than microfibers such as rayon and viscose, which are usually used to make pads. They’re also much smoother in composition, resulting in a thinner and softer product that doesn’t need to be changed as often as regular pads, and making them a less expensive option. That’s a big breakthrough in a country where millions of women don’t use sanitary pads or tampons at all due to their relatively high costs and the taboos attached to discussing menstrual hygiene.

But Chandra and his team want to change that with pads that can last longer. “We aim to produce these pads with more absorption capacity so even in high discharge conditions, only a single pad will be sufficient. So, overall, for a complete menstruation cycle which lasts for five to six days, this will be economical,” he said.

Cleaning contaminated concrete

The Sandia National Laboratories is a multi-mission laboratory operated by Sandia Corporation, for the U.S. Department of Energy’s National Nuclear Security Administration. Craig Tenney, a chemical engineer at Sandia National Laboratories, has been thinking about what happens if concrete gets contaminated by a chemical agent. “We can’t just rip out and replace the affected concrete — that would be too expensive,” said Craig. “We need to decontaminate it and make it safe. The public has to be confident enough to come back and use the affected facility.”

The project, funded by Sandia’s Laboratory Directed Research & Development program, uses computer simulations to examine how chemical agents soak into and bind within concrete. Craig’s team modelled several long-lasting chemical agents and monitored how molecules of these agents act within nanometer-sized pores such as those found in concrete. So far, they have determined how strongly various chemical agents stick to concrete pores as well as which ones clump together. By comparing their results to the small amount of experimental data available, the team was able to validate their findings, an encouraging starting point for further research. While there is still work to be done, Craig is confident that the computational models may lead to more accurate field tests and improved decontamination techniques.

“Yes, it would be great from a scientific perspective to just understand what’s going on, but from an engineering point of view, it would also be darn nice if we could take that understanding, tailor our approach for decontamination and make it better,” said Craig. “This is a national lab-scale problem and there are lots of little pieces that need to be put together to solve a big problem. If the unfortunate ever does happen, at least we [will be] prepared.”

If you have a research story to share, get in touch with the IChemE Blog Elves and you could be featured in next month’s post.