Sustainability Success Story – Mohammed Farid

10th May 2024

New technology to improve cold chain management of fresh foods

Approximately 7% of worldwide food loss occurs during distribution, including the Last Mile, equivalent to $37 billion in just the Australian market.

Professor Farid has been researching phase change materials (PCMs) for thermal management for almost 40 years. In 2022, he established spin-off company from the University of Auckland called PhaseFoam, aiming to commercialize a revolutionary heat-absorbing material. This technology has the potential to transform the food cold chain, offering substantial economic and environmental benefits with significant improvements in food quality.

The developed panels, manufactured based on patented encapsulation technology, consist of an innovative heat-absorbing material, providing an advanced temperature management solution tailored for the cold chain industry, especially in refrigeration trucks transporting temperature-sensitive food products. These panels absorb and release heat as they transition between solid and liquid states, offering additional cooling to maintain food at a safe temperature (4°C for chilled products) during door opening or engine failure.

The technology underwent commercial testing using stationary refrigerated trucks containing food in August 2022 in Chicago, demonstrating significant benefits in sustaining food quality (grapes) during storage. Further testing will be conducted this summer.

Currently an Emeritus Professor following 27 years of work as a full professor at University of Auckland, New Zealand.

Farid was elected in 2000 Fellow of the Institution of Chemical Engineers (FIChemE) and has received several international awards such as the Marie Curie Fellowship in 2010 by EU and the Lifetime Achievement Award in 2015 by the International Association of engineering and Food (IAEF) in which he represented New Zealand for almost 20 years.

Farid has been active in organising and attending food conferences such as ICEF and IFT. He is also a member of the editorial board of a few journals among them is the journal of Food Engineering

With his colleagues, he has established the Food and Bioproduct cluster in the Department of Chemical and Materials Engineering 25 years ago, giving opportunity for chemical engineers to play important role in food processing in collaboration in collaboration with food scientists.

Tell us briefly about your work in health and wellbeing?

My research focusses into three areas; the non-thermal processing of food, improving food cooling technologies (on-farm cooling of milk), and minimising food waste during transportation, all aiming to produce and sustain food of high quality by reducing the thermal abuse to food without compromising its safety.

Tell us more about your work with fresh food products using non-thermal processing?

To produce nutritional and fresh food, we have introduced non-thermal processing to New Zealand more than 20 years ago. High-pressure processing (HPP) was applied for pasteurising liquid and solid food with almost no heating. The extreme high pressure used inactivate bacteria but has no impact on small molecules such as vitamins. It was also used to increase the nutritional value of some products such as Manuka honey and milk. The pulsed electric field (PEF), which is based on carrying electroporation in the bacteria cell’s wall for pasteurisation or in the wall of plant seeds to enhance extraction. The PEF unit was the first to be built in the southern hemisphere using fully local expertise.

Our innovative and unique research was focussed on the use of thermal processing in combination with PEF or ultraviolet (UV) to produce an extended shelf life (ESL) of liquid food products such as milk. The objective was to produce improved quality milk, lying between pasteurised and UHT milk. The incorporation of UV or PEF with the thermal processing reduced the temperature needed to have a safe and more nutritional product.

What has been one of the most impactful activities you have been involved in?

The cooling of milk amounts for 30% of the daily energy use at a dairy farm. The fast cooling of milk immediately after milking is essential for preserving milk quality and hygiene until processed for consumption or used to manufacture other dairy products.

In existing practise, milk from farms is usually sent to a vat to be cooled ‘slowly’ until collected. Recently, New Zealand dairy farmers have been instructed to upgrade their dairy-shed milk cooling systems to meet the new legislation (Operational code NZCP1-2017). This new regulation requires dairy farms to upgrade their milk cooling systems. Any milk not meeting the new cooling criteria stands the risk of being rejected and discarded. But this up-grading results in higher upfront costs as well as higher energy running costs.

Energy-efficient milk cooling systems directly impact the costs and profitability of dairy farms. Here in New Zealand, most of the power companies provide night tariffs which are significantly lower than normal tariffs. With the use of a thermal energy storage (TES), it is possible to shift the energy demand from day to night. This will allow dairy farms to save on their energy bills. More importantly this will allow farmers to run their existing chillers without the need for upgrading to higher capacity.

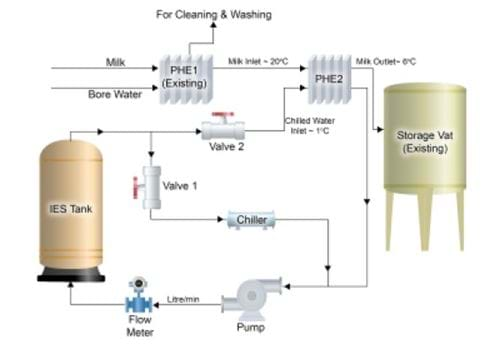

In this project, we have designed and constructed an innovative PCM-ice storage system that competes in performance and cost with existing ice storage systems such as the ice on tube.

The units currently available on the market are too expensive and bulky – don’t fit into the New Zealand systems and don’t give enough of a return.

What we have set out is something that is both cheaper to manufacture, compact, energy efficient and has low refrigerant holdup. A laboratory scale unit was first built and tested at University of Auckland, followed by the construction of commercial unit installed in a farm in Hamilton.

Farm owner, Stuart Husband

“The milk quality result is improved from B to A+ when the ice storage system is installed. This is because the milk is chilled down quickly, so there is no time for bacteria growth, which is great for us.”

Visit our Sustainability Hub to access a suite of on-demand training courses that are free to members, and knowledge resources that will help you embed sustainable principles and practices into everyday work and life.