Catalysis and Reaction Engineering

Webinar: Can We Change the Thermodynamics of Hydrogen Production, Sustainable Fuels Production and Direct Air Capture?

- Date From 7th October 2025

- Date To 7th October 2025

- Price Free of charge.

- Location Online: 14:00 BST. Duration: 1 hour.

Overview

This webinar celebrates the award of the Sharma medal to Ian Metcalfe, RAEng Chair in Emerging Technologies and Professor of Chemical Engineering, Newcastle University.

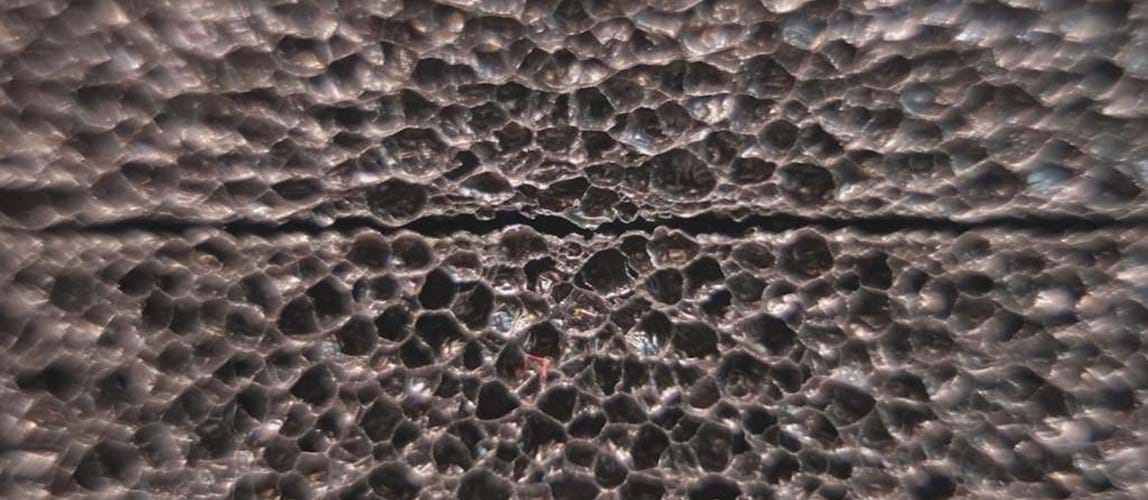

Materials with oxygen storage capacity can be exploited to make chemical reaction processes more efficient. The original way of making hydrogen some 120 years ago used this oxygen storage concept. The steam-iron process involved the reduction of iron oxide in a fuel gas to produce particulate iron; this iron was then oxidised in steam to produce hydrogen and magnetite. Such processes have the advantage of separating the products of the fuel oxidation from the hydrogen product leading to a greater thermodynamic efficiency. As a result of their inherent advantages, chemical looping processes (as they are known) are once again in the research spotlight.

Of interest is oxygen carrier material design to fit the chemical process in question (using this approach we have demonstrated novel approaches to achieve super-equilibrium conversions for the water-gas shift reaction), oxygen carrier synthesis and oxygen carrier characterisation (particularly in-situ or even operando). Interestingly the reactor operation described above can be ‘reversed’ to perform the reverse water-gas shift reaction (RWGS) and again achieve super-equilibrium conversions. This reaction is key for sustainable fuel production from hydrogen and carbon dioxide.

Separating highly dilute species presents significant challenges due to both thermodynamic and kinetic constraints. Here, we introduce a molten-carbonate membrane that leverages ambient energy from a humidity gradient to concentrate CO2 from a 400 ppm input stream—similar to atmospheric air—into a more enriched output air stream. The substantial difference in water vapour concentration across the membrane enables CO2 transport against its natural concentration gradient at very high permeation rates.

IChemE's Sharma Medal recognises sustained outstanding research contributions in chemical engineering across an individual’s career. The medal is named after Professor Man Mohan (MM) Sharma, was a highly respected professor of chemical engineering from India, director of the Institute of Chemical Technology in Mumbai, and the first Indian engineer to be elected as a Fellow of the Royal Society, sponsored through a kind donation from Dr A V Rama Rao (Founder, Avra Ltd) and Professor J B Joshi (ICT Mumbai).

Speaker

Ian Metcalfe, Professor of Chemical Engineering, University of Newcastle

Over the past thirty-five years Ian has built-up an externally funded research programme with a strong equipment base. This has been achieved through a balanced combination of individual and collaborative grants and contracts. The focus of my research is in applying chemical engineering to problems in the area of catalysis, high temperature membranes and dynamic reactions (or chemical looping). While the end goal is often to demonstrate a novel process a fundamental understanding of the problem and its underlying science always is necessary. He has published more than 170 refereed papers and supervised around 60 PhD students.

The material presented has not been peer-reviewed. Any opinions are the presenter’s own and do not necessarily represent those of IChemE or the Catalysis and Reaction Engineering Special Interest Group. The information is given in good faith but without any liability on the part of IChemE.

Back to events