Clean Energy

Combustion Aerothermal Design

- Date From 7th February 2019

- Date To 7th February 2019

- Price Free of charge

- Location Online

Overview

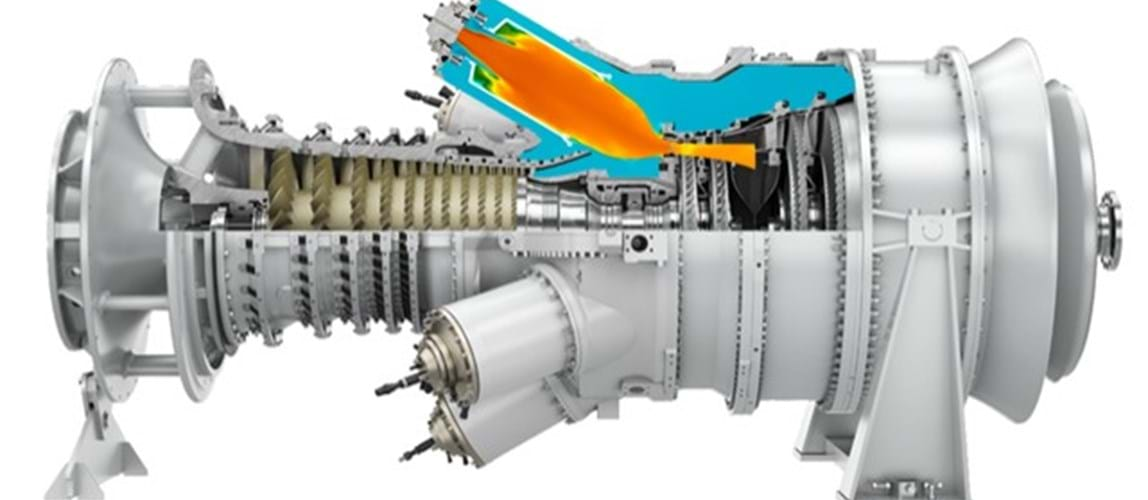

Even with the promotion of nuclear and renewable energy for reducing carbon foot print, gas turbines are still considered as the prime source for operating mechanical drives and generating power. Siemens is constantly striving to achieve lower emissions and reduction in emissions such as NOx and CO which is the prime target for every gas turbine manufacturer. Research and development is focused on reducing emissions and improving the performance and efficiency of these engines.

In Lincoln, Siemens manufactures small range gas turbines from a power range of 5 to 15MW for both mechanical drives and electrical power generation. Customers include Oil and gas platforms, small scales manufacturing industries such as car manufacturers and Universities with special power requirements. Combustion at all loads and ambient conditions plays an important role in operating the engines. Lower NOx and CO emissions are currently achieved through Dry Low Emission (DLE) and a Ultra Low Emissions (ULE) combustion system which operates on a lean premixed fuel and air technology. However, this mode of combustion process will lead to combustion dynamics which could lead to destruction of hardware. Therefore, design of combustion system for low emission gas turbines to the future generations is very much intended.

The webinar will describe the work that Dr. Sadasivuni has been doing at Siemens with the design and development of future combustion systems for small gas turbines.

Speaker

Dr. Suresh Sadasivuni is the team leader for combustion aerodynamics group at Siemens Industrial Turbomachinery Ltd, Lincoln, UK. His team constantly works on the future generation combustion systems development with DLE and ULE technology. Dr.Sadasivuni completed his doctorate from Loughborough University, UK with his research work related to combustion modelling using Computational Fluid Dynamics (CFD). Dr. Sadasivuni joined Siemens, UK in 2009 and has progressed from a senior engineer to team management level. Prior to his PhD, he worked in General Electric Company (GE India) in the Engineering Analysis for Center of Excellence in combustion system design. Dr. Sadasivuni received Master’s from Indian Institute of Technology, Madras, India and graduated from Andhra University, India with a Mechanical Engineering degree.

The material presented has not been peer-reviewed. Any opinions are the presenter’s own and do not necessarily represent those of IChemE or the Clean Energy Special Interest Group. The information is given in good faith but without any liability on the part of IChemE.

Format

A one-hour online session: 40 minutes' presentation + 20 minutes' Q&A.

Duration (for CPD recording purposes): up to one hour.

If you are recording mandatory CPD you should refer to your own regulator's requirements as recognition of CPD hours may vary.

Webinar archive

This webinar is free of charge and open to all to attend, but if you wish to access the slides and a recording to replay on demand then you'll need to be a member of the Clean Energy Special Interest Group.

If you're interested in giving an online presentation to our international community of chemical engineers, we'd like to hear from you. Please email special interest groups support team with information on yourself and your proposed talk.

Back to events