Palm Oil Processing

Seminar presented net zero plans

1st November 2021

Overview

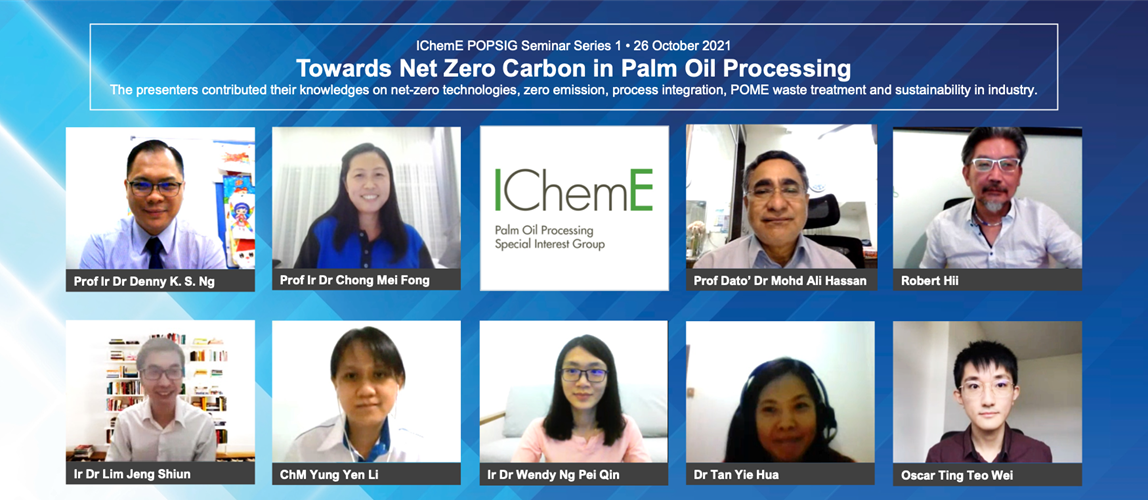

The POPSIG Seminar Series 1: Net Zero concluded on 26th October 2021 at 10:30 EDT (15:30 BST). Five professionals exchanged their views about the net-zero technologies to tackle climate change. The professionals discussed the feasible strategies to succeed 1.5°C pledge and drive the nation towards net zero.

Welcoming address

Ir Dr Wendy Ng Pei Qin welcomed all the speakers and audiences to the first POPSIG seminar series that was launched to share the latest academic and industrial advancements about the improvement in palm oil processing to all stakeholders and the public.

In her welcoming address, she gave an overview about the greenhouse gas (GHG) emission reduction and net-zero emission targets. The former one is established to ensure reduction at a rate that is consistent to the company's goal, while the latter describes that the companies take responsibility on the emissions that have yet to be reduced, or remain unfeasible to be eliminated.

Ir Dr Ng stated that the palm oil industry is improving to tackle GHG emission, while the recent research has actively promoted sustainable palm oil production to transition the industry towards net-zero emission era. These technologies convert the emissions during palm oil processing into useful applications and this moves to industry closer to achieve the net-zero carbon emission target.

She highlighted that the seminar would share the latest academic and industrial advancements in achieving net-zero carbon emission in palm oil processing. She welcomed the six professionals for contributing to the seminar.

Opening speech

Professor Ir Dr Chong Mei Fong introduced the theme of POPSIG for the year of 2021: Correcting the misperception on palm oil. She outlined that the core activities supporting the theme are webinars, university roadshows, newsletters, and awards and bursaries.

In 2021, POPSIG has hosted and co-organised 20 webinars, which contributed to the increase of net followers by 84 users, the engagement improved by 4,000, and the promotional materials reached 14,000 people.

POPSIG also engages with the future generation of chemical engineers through the regular University Roadshow, including in Peninsular and East Malaysia, Brunei and Indonesia. Through this programme supported by Malaysian Palm Oil Council (MPOC), in conjunction with Sawit Anugerah Tuhan campaign, POPSIG connects the third-level students with the industry and share the palm oil sector as one of their career pathways.

POPSIG offers numerous awards and bursaries at university and industry levels. They include: the annual Best Final Year Design Award, Research Project Bursary, Travel Bursary for Conference, Article Honorarium, online quizzes, and many more. In 2021, POPSIG's awards that accounted for 18,670 MYR had benefited 50 individuals and 11 institutions.

POPSIG is actively engaging with the Ministry of Plantation Industries and Commodities (MPIC), also known as Kementerian Perusahaan Perladangan dan Komoditi (KPPK). Besides, the organisation works closely with Malaysian Palm Oil Board - MPOB (premier government agency for palm oil sector), Malaysian Palm Oil Council - MPOC (for promoting market expansion), Malaysian Palm Oil Certification Council - MPOCC (for the development of MSPO certification scheme), and many more.

To support the education, over 18,000 MYR have been utilised to benefit 50 individuals and 11 institutions in both Peninsular and East Malaysia. POPSIG activities revolve around the theme of responsible production (including sustainability, climate change, environmental protection, net zero emissions), identification and management of major risks and digitalisation. In line with IChemE100, POPSIG activities have also covered the themes of energy, environment and sustainability.

Presentations

Palm oil mill effluent (POME) waste treatment

Professor Ir Dr Chong Mei Fong presented the POME waste treatment - a journey in biogas development and its challenges. POME is a major source of biogas. Professor Chong illustrated that from fresh fruit bunch to clarified crude palm oil (CPO), POME is generated as the wastewater of the processing.

Conventionally, POME treatment requires 7 ponds that typically cover 70% of the mill area. During the treatment, organic substances degrade gradually for 300 days, and hence, the process releases GHG, including methane and carbon dioxide. At the initial stage, biogas and methane are released from the anaerobic pond while facultative pond at the later phase stores the effluent, in which most organic matters have been harvested and completed the conversion into GHGs.

Initiatives converting POME treatment into value-added processes improve the palm oil processing. Clean Development Mechanism (CDM), which is a carbon trading mechanism for reducing GHGs, has begun in 2007 and was overseen and supported by Malaysia Energy Centre. The Malaysian Federal Cabinet approved the National Renewable Energy Policy and Action Plan (NREPAP) in April 2011, and has started the feed-in-tariff (FiT) mechanism since 1st December 2011.

Sustainable Energy Development Authority (SEDA) in Malaysia is a statutory body formed under the Sustainable Energy Development Authority Act [Act 726]. SEDA functions to administer and manage the implementation of the FiT mechanism which is mandated under the Renewable Energy Act 2011 [Act 725].

Under National Key Economic Areas (NKEA), EPP5 aims to develop biogas at palm oil mills. Malaysia’s palm oil industry is regulated by MPOB. The agency awards licenses across the value chain from seed producers to export of palm oil as well as developing policies, guidelines and practices to help monitor and assist the industry. The board had rolled out that starting from 1 Jan 2014, all new palm oil mills and existing ones applying for throughput expansion in the country should install full biogas capture or methane avoidance facilities.

EPP5’s target outlined that:

- Malaysia regulations requires ALL palm oil mills to install biogas facilities by 2020.

- Biogas plants will be developed at the 500 mills over the next 10 years.

- Of these, 250 mills will target to supply electricity to the national grid by 2020.

- Another 233 mills will capture biogas to be used as fuel for their own boilers.

- The balance of 17 mills will use the methane gas for both options.

Challenges to the current initiatives include the limited market or demand because FiT is quota-based. Other downsides include remote areas with difficult grid connection and the high capital costs. The implementation is also dependent on the responsibility of the mill owner. Other challenges include the selection of biogas versus effluent treatment, and imbalance between supply and demand. The policy is supportive (motivation and regulation approach) but too restricted (micro approach).

Professor Chong suggested that the initiatives should have an overarching policy (macro approach) allowing an active balancing of demand and supply to make impact. Biogas versus effluent treatment also requires integration and simultaneous solution.

Process integration using pinch analysis

The Prime Minister of Malaysia, Yang Amat Berhormat Dato’ Seri Ismail Sabri Yaakob has tabled the 12th Malaysia Plan (12MP) or Rancangan Malaysia ke-12 (RMK12), which pledges the nation to become a “carbon neutral country by 2050 at the earliest”, as announced on 27th September 2021.

Ir Dr Lim Jeng Shiun discussed that the user should refer to the carbon management hierarchy for oil palm supply chain. He described that the improvement on the complex core process side, in addition to that on the utility system, should be done to enhance the overall energy efficiency. He also shared the impact of efficiency improvement of different process layers on the utility requirements.

Pinch analysis for optimal design can be done using graphical or algorithm approaches. While maximising the impact of renewable energy integration, he addressed that solar thermal itself may not be economically attractive, but proper process integration is required. Both in-process and end-of-pipe analysis needs to be performed to maximise thermal energy saving. Pinch analysis can provide multiple deep insights into the utility and process improvements for thermal, electricity, water and emissions, while the technique can also be applied for other resource minimisation analysis.

Sustainability in industry

ChM Yung Yen Li from IOI Edible Oils Sdn Bhd presented the approach to systematically minimize energy wastage at the mills. On utilities saving, vent economizer is used to recover heat from flash steam from condensate tank.

To practise green energy initiatives, GHG emission is monitored at the by-product stream. Shorter cycle time reduces electricity consumption by 40%. Saving in chemical usage contributes to the reduction of GHG emissions. Sludge is streamed to reactor for the bacterial digestions. About 85% of the treated water is used as industrial water.

The more environmentally friendly LNG replaced diesel for Geka boilers to reduce carbon footprints. The steam generated by biomass boiler has increased to 2.61 tonne steam per tonne EFB from 2017 to 2020. The firm also uses bio-lubricants that is biodegradable and non-toxic to human beings and aquatic habitats. Wet scrubber was used to improve the air quality and half the emission, as restricted in the Clean Air Act.

Zero emission

Professor Dato’ Dr Mohd Ali Hassan lectured about the concept of zero emission, waste-to-wealth and biomass-to-business strategies. He emphasized the 3Ps principles: profit, people and planet, in addition to the sustainable development goals (SDGs).

Adding values to biomass is vital because they are not waste, but renewable sources. Biogas capture during POME waste treatment is important to generate bioenergy and bio-products. POME can also be converted into biogas and biohydrogen for producing biomass energy besides manufacturing bioplastic (PHA). Through bioreactor, empty fruit bunch can be used to make bioplastic (PLA) and bioethanol.

In his JICA-JST SATREPS project, the air and water pollutions could be eliminated to safeguard the biodiversity conservation. The installation of a modern biogas capture system and the replacement of the extensive lagoon area into a biomass business area are critical for developing bioeconomy in the rural area. Biogas provides electricity for new business and contributes to zero-emission plans.

By sealing the lagoons, it will reduce GHG emissions, prevent pollutions, promote water recycling and create job opportunity for biobusiness. Professor Ali also stated that the development of new oil palm plantations in the tropical rainforest will no longer be sustainable.

Net zero

Robert Hii shared that the agricultural sectors are being enrolled in the fight against climate change. He shared that Global Warming Commission in the US revealed a plan that will be dependent on farms and forests to absorb emissions; Danish authorities introduced legally binding legislations to reduce GHG emission by half in 9 years time starting from 2021.

Robert also discussed that palm oil can be the first net-zero vegetable oil because of its industrial advantages including the contributions by NGOs to identify the emission sources. He outlined that company-specific emissions must be calculated to set firm targets, and the emission savings must be quantified.

Robert also shared that it is important to reduce CO2 emission stepwise from 2.85 Mg CO2/ton to 0.45 Mg CO2/ton to Net Zero. The first step is emission reduction through certification demands, and followed by mill actions towards net zero. These include to adhere to the qualified certifications, including ISCC, MSPO, RSPO to achieve 0.38 Mg CO2/ton and to protect high biodiversity value areas. Other key actions include to convert known mill wastes into green energy to power the mill operations, increase OERs at mill to decrease carbon footprint, and quantify emissions.

Back to group news