Palm Oil Processing

Sime Darby Plantation Research Crowned Winners at IChemE Malaysia Awards 2022

15th November 2022

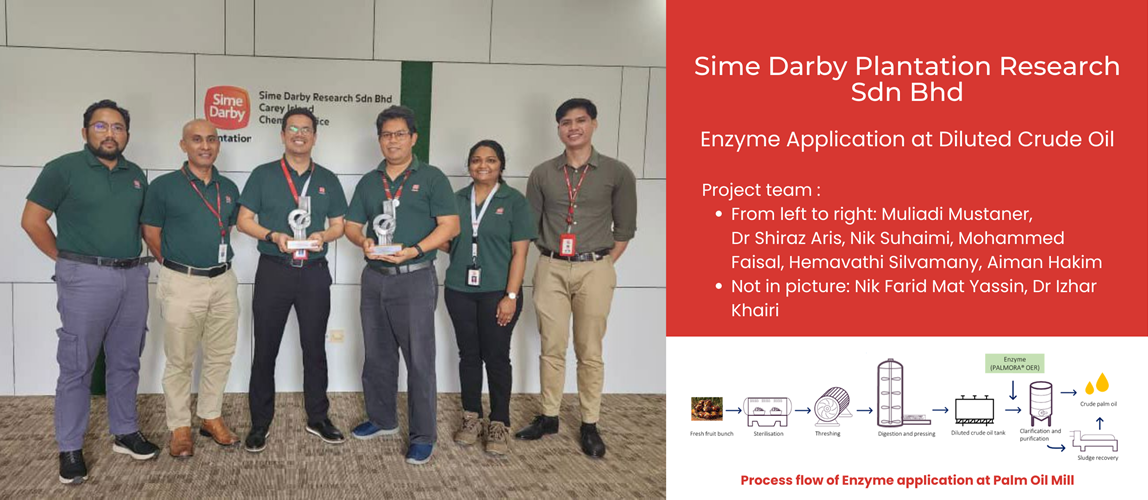

Enzyme Application at Diluted Crude Oil, Sime Darby Plantation Research Sdn Bhd

As the world transitions into a low-carbon or carbon neutral economy, businesses are driven towards ensuring that their processes and production comply to relevant environmental and sustainability standards. Sime Darby Plantation (SDP) has long committed to sustainable practices and continue to play a leading role in shaping a sustainable future for the palm oil industry. Through its research and development initiatives, both direct and indirect environment as well as sustainability targeted outcome have been achieved in the past. One of the innovative breakthroughs in milling process efficiency improvement is a process developed by Sime Darby Plantation Research (SDPR) and Novozymes, an enzyme developer, on the application of bio-based enzymes to enhance oil recovery. The combination of a bio-based raw material and the expected increase in oil recovery aligns well to the overall objectives of sustainable operations and carbon neutrality.

The enzymes in this innovation are designed to release trapped residual oil in unbroken cells that are found in the process fluids arriving from the mill’s press operations. The enzyme features thermophilic properties that enables dosing into the Diluted Crude Oil (DCO) prior to entering the Vertical Clarifier Tank (VCT). The key highlights of the innovation, apart from the enzyme design, is the standalone dosing system that consist of an enzyme skid, dosing pump, an inline mixer and an automated process management system that ensures optimum dosing rates and data analysis with minimal human intervention. The enzyme treatment operates on a four to six hour targeted “process window” that is available between the dosing point and separation process in the VCT. The outcome is the realisation of additional free oil at the top layer of the VCT and reduced amount of trapped oil in the emulsion layer and tank underflow. The process can be easily adopted due to relatively low investment cost on the retrofits required to the existing milling process.

Implementation of the enzyme programme has been carried out on a commercial scale at SDP oil mills since 2020. The measurement of success of the programme is in the oil extraction rate (OER) achieved at the respective mills. To date, average OER increments of 0.72% have been recorded for the 10 SDP mills installed with the dosing system. Revenue generation from the dosing programme is estimated at RM6.0 million/mill/year for SDP and, potentially RM2 billion/year, if deployed in all oil palm mills in Malaysia.

On top of owning the intellectual rights (IP) of the current enzyme dosing system, SDP continues to develop solutions to enhance milling processes, especially on the use of enzymes with robust features such as temperature tolerance or satisfactory effectiveness at lower temperature environments. The enzyme application methods would also require further R&D work to explore effectiveness at the different milling process stages.

Recently, the SDPR bio-enzyme team was acknowledged for their efforts in the enzyme development programme at SDP. The team received IChemE Malaysia’s awards in two categories: palm oil and sustainability. As local winners of the award, SDPR is automatically shortlisted as one of the contenders representing Malaysia for the Sustainability Award at the IChemE Global Awards which will be held in Manchester, UK, on 17 November 2022.

The award is a recognition and at the same time, a motivation for the team to continue its journey towards rolling out more R&D initiatives that will realise larger sustainable and environmental goals for SDP. It is a privilege and honour to represent Malaysia and the palm oil industry at an international event.

Project team

In the header image (from left to right): Muliadi Mustaner (Chief Engineer II), Dr Shiraz Aris (Head, Processing Technology), Nik Suhaimi (Chief Engineer I), Mohammed Faisal (Head, Processing & Engineering), Hemavathi Silvamany (Senior Engineer), Aiman Hakim (Senior Engineer). Not in picture: Nik Farid Mat Yassin (Chief Engineer I), Dr Izhar Kahiri (Chief Engineer II).

Contributors

This article was prepared by the project team at Sime Darby Plantation Research Sdn Bhd.

Full article

More about SDP and SDPR

To learn more about the commitments at SDP and SDPR, please visit: https://simedarbyplantation.com/

Back to group news