Safety and Loss Prevention

Webinar: Pixel-Perfect Safety - Virtual Twins and the Simulation of Plant Processes

- Date From 16th September 2025

- Date To 16th September 2025

- Price Free of charge.

- Location Online, 12:00 BST. Duration: 2 hours.

Overview

This webinar acts as an excellent introductory event to IChemE's Advances in the Digitalisation of the Process Industries Conference.

Bhuvan Patel of Syngenta will talk about the use of a virtual twin for enhancing decision making, improving efficiency and reducing plant downtime and Roger Rayner of Iconic Simulation will talk about the use of dynamic process simulation for hazard evaluation and management using a case study of an exothermic batch reaction.

The panel discussion will explore topics such as reactive versus proactive use, the use of learned models and industry capability status.

Use and Benefits of Virtual Twin in Asset Integrity World

For this event, Bhuvan would like to share Syngenta's learnings and use of a site's virtual twin from an overall site efficiency perspective that enables Syngenta to enhance ways of working in various disciplines like outage management, project management, risk-based work selections, safety and operational training.

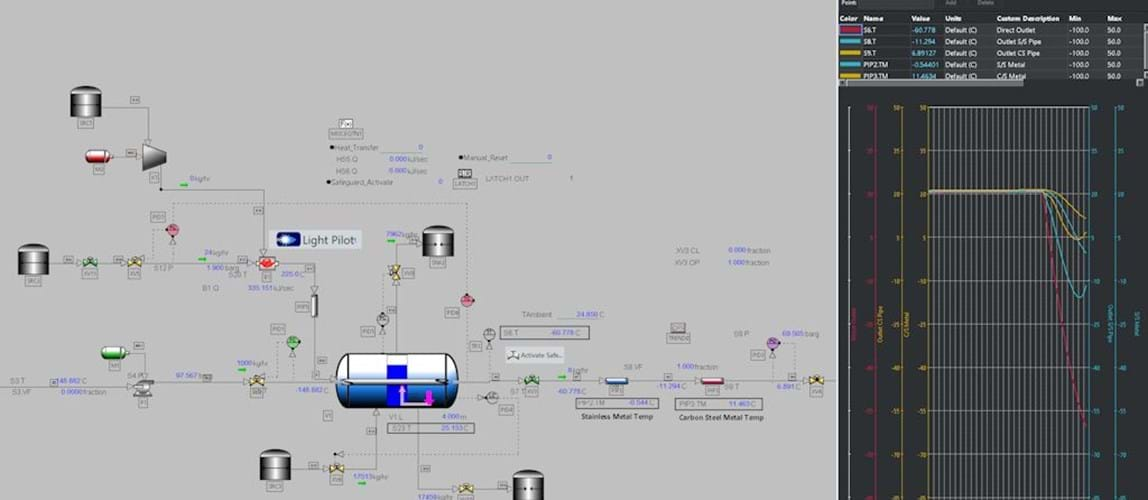

Benefits of Dynamic Simulation for Hazard Evaluation and Management – Batch Reactor Case Study

Dynamic simulation has been used extensively in continuous hydrocarbon processing to understand transient safety events and test safeguards, such as flare systems. However, its use in batch processing has been limited. It offers many benefits that steady state simulation cannot provide. For example, demonstrating batch cycle time by correctly sizing jacket heating and cooling systems. This webinar will present a case where a jacket cooling system must be correctly sized for an exothermic reaction to avoid thermal runaway and loss of containment.

Speakers

Bhuvan Patel, Asset Integrity and Reliability Manager, Syngenta Crop Protection - North America

Bhuvan is an experienced Mechanical Engineer with over 13 years of experience in the Oil & Gas, Chemical, and Design companies. Demonstrated expertise across multiple roles including Piping Engineer, Project Manager, Mechanical Integrity Lead, and Reliability Lead, consistently driving operational excellence and innovation in complex industrial environments. In my current role, Bhuvan serves as Asset Integrity and Reliability Manager for Syngenta's St Gabriel site leading a team of Mechanical Integrity and Reliability Engineers to enable safe and reliable operations.

Roger Rayner, Director, Iconic Simulation Limited

Roger is a Chartered Chemical Engineer and Fellow of IChemE with over 30 years’ experience. He has been an independent consultant for over 10 years and specialises in process simulation. Roger has worked in many different industries and demonstrated success in applying process simulation to all types of processes. His experience encompasses steady state, hydraulic and dynamic simulation and through the years has developed a modelling sixth sense coupled with a proven delivery technique.

The material presented in this event has not been peer-reviewed by IChemE. Any opinions are the presenters' own and do not necessarily represent those of IChemE or the Safety and Loss Prevention Special Interest Group. The information is given in good faith but without any liability on the part of IChemE.

Webinar recording

Member-exclusive content

Become an IChemE member to enjoy full access to this content and a range of other membership benefits. If you are already a member, please log in.

Back to events